Skip to product information

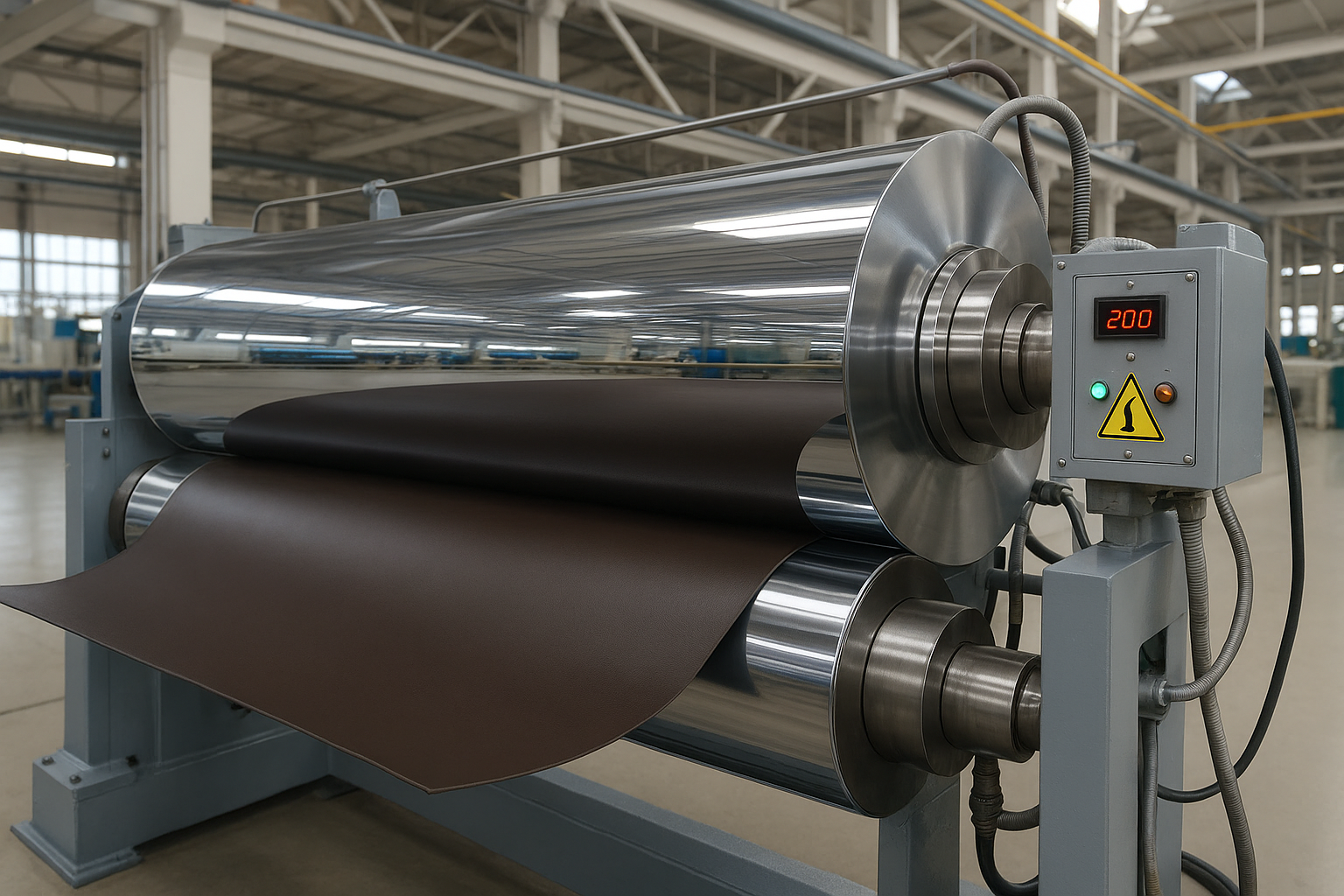

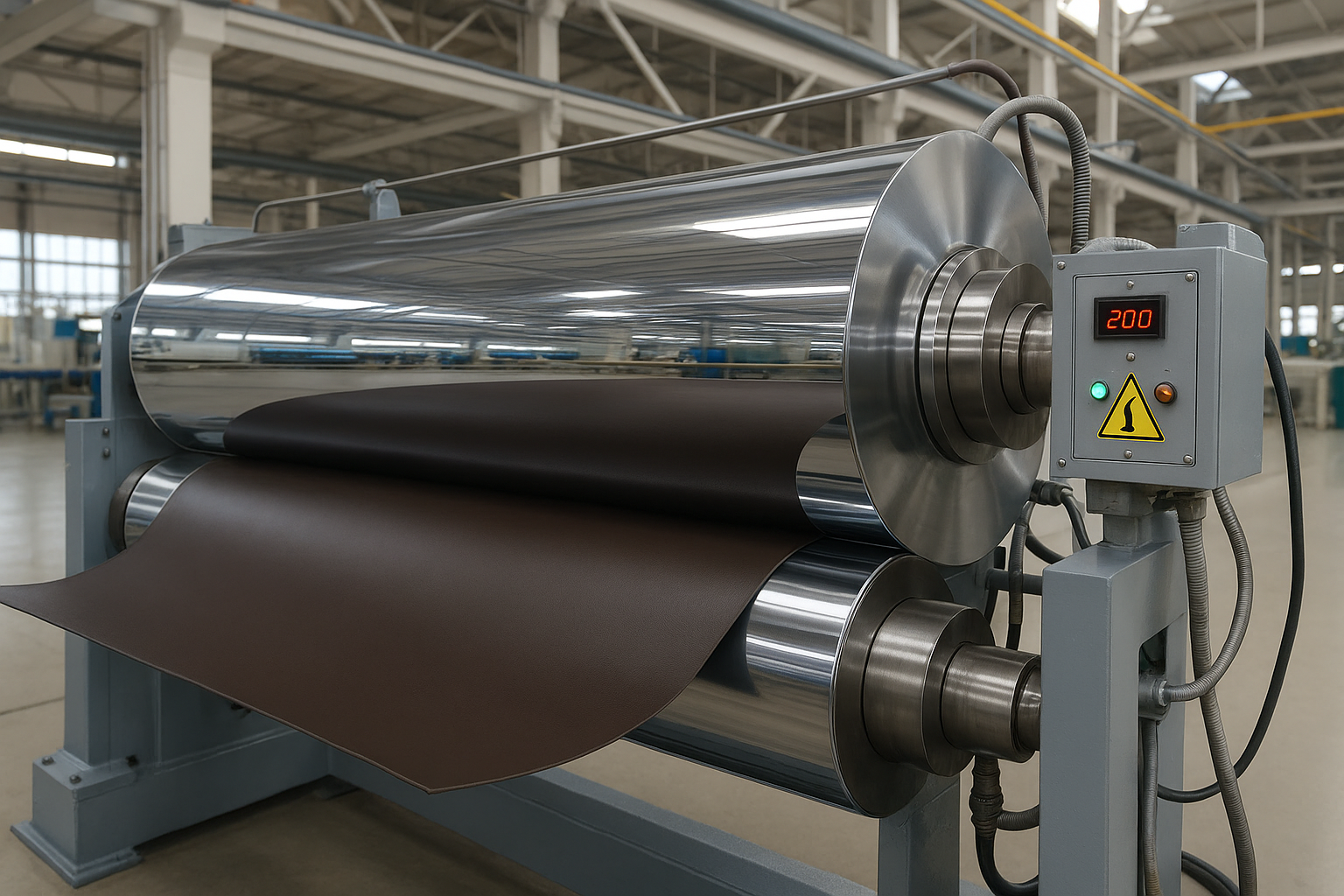

Heating roller

I. Product Overview

II. Key Features

III. Common Specifications

IV. Typical Applications

Pickup currently not available