Skip to product information

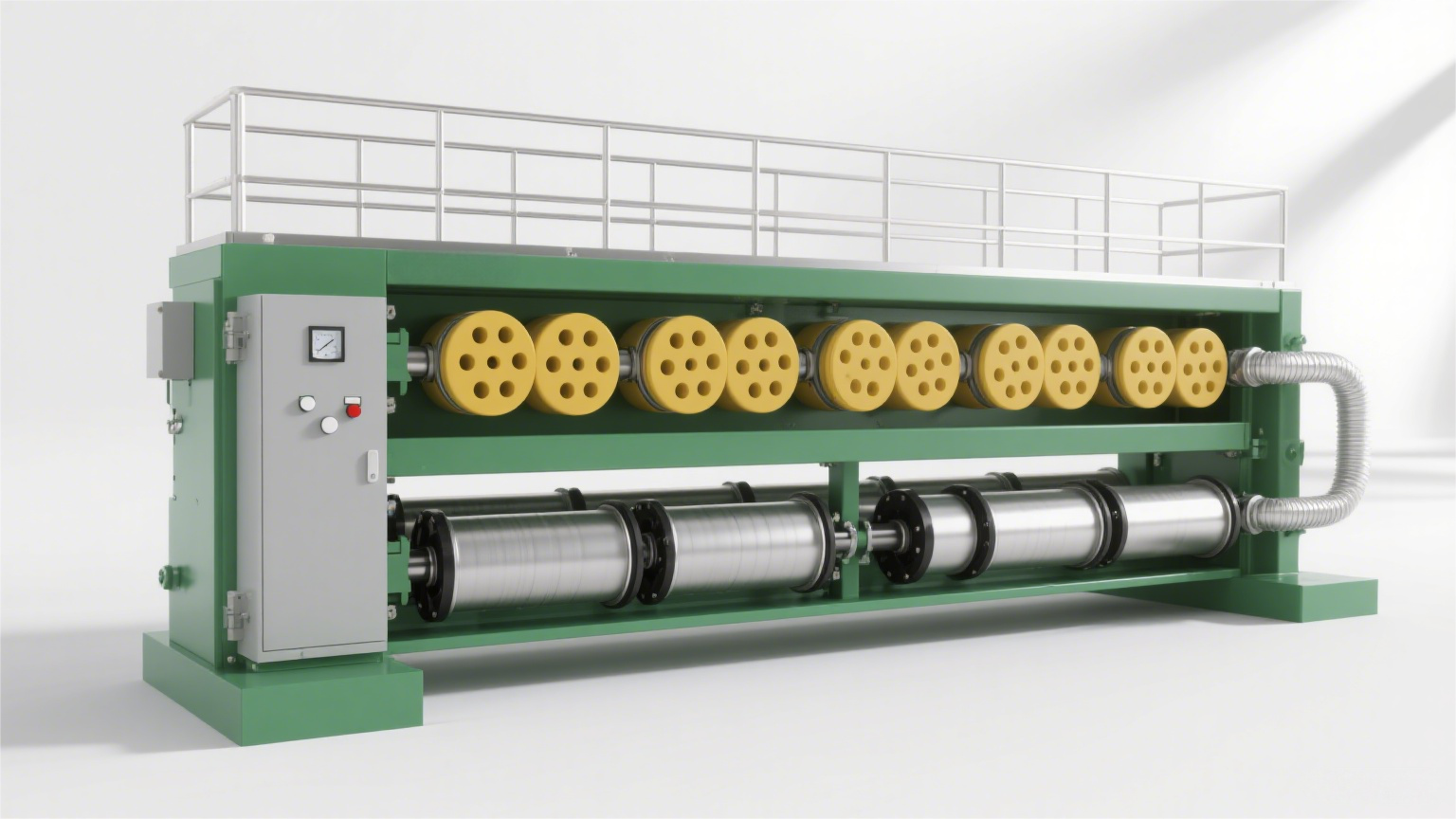

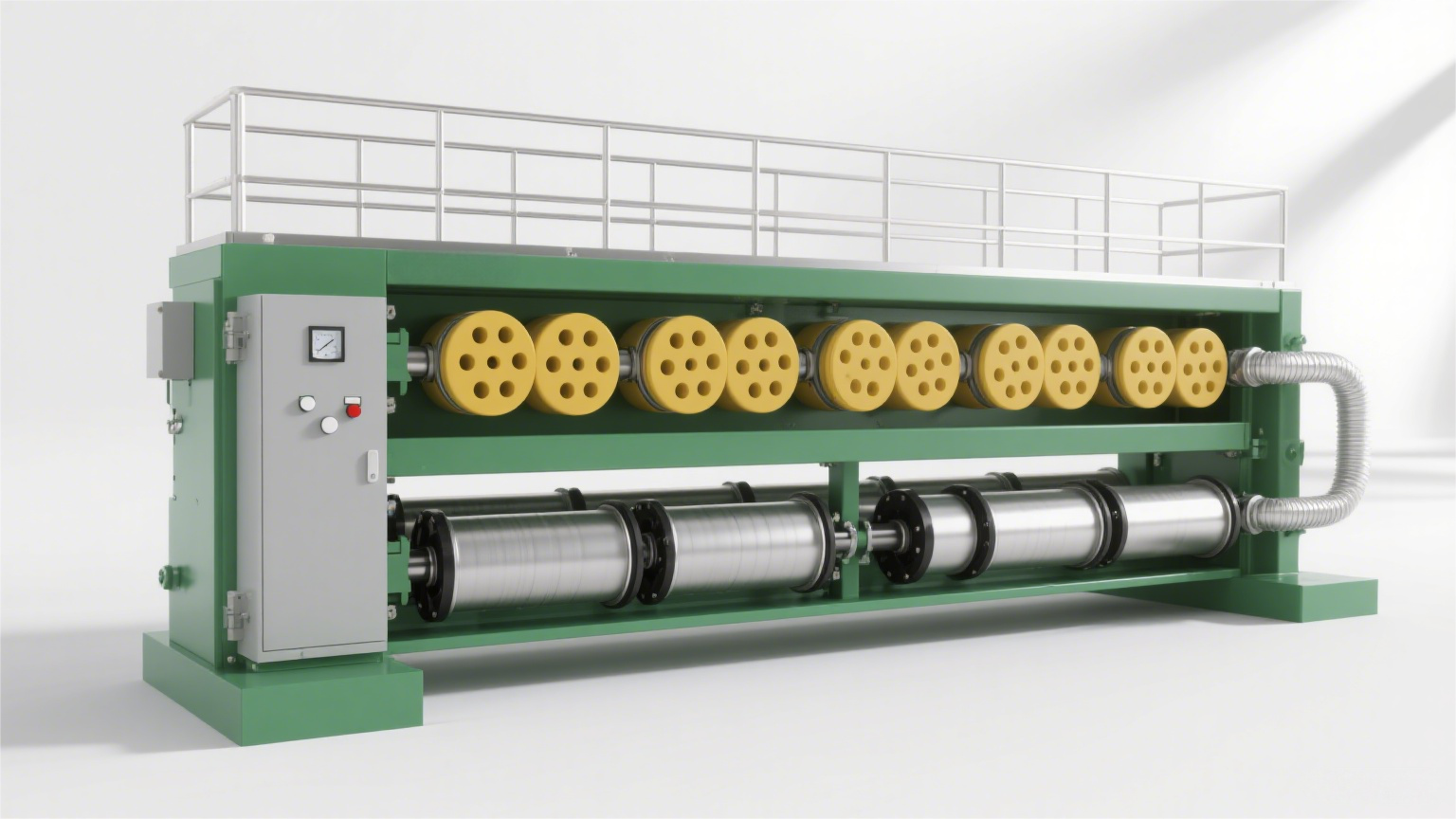

Water Cooling Machine

I. Product Overview

II. Core Features

(1) Efficient Cooling

(2) Precise Thickness Control

(3) Stable Operation

III. Common Specifications

(1) Equipment Parameters

(2) Roller Parameters

(3) Cooling System Parameters

IV. Typical Applications

Pickup currently not available